Ved Sassomeccanica (India) Pvt. Ltd.

(An ISO 9001:2008 Certified Company)

Plant & Machinery

RAW MATERIAL CUTTING SHOP

Approved steel plates of respective grades for different types of bogie frames are cut in batches of 4 or 8 Nos in three CNC machines.

- CNC Plasma (High Definition) for plates upto 32mm. Edge preparation 30°, 45°, 60° in x-y direction on long plates from 5 axis CNC Bevelling Torch on above machine.

- CNC Oxycut Machines for plates above 32mm

- CNC Plasma for plates upto 20 mm

Critical dimensions and profiles are checked with gauges and records are maintained.

CNC Plasma (H.D.) OXY Cutting (25x13000). Plazma Cutting : Steel Plates upto 32 mm thick. Oxy Cutting : Steel Plates upto 100 mm thick

PRESS SHOP

All types of dies, punches and gauges for each type of bogie frame to be used in CNC press brake and Hydraulic presses are inhouse designed and developed.

- CNC Press Brake 450 MT, 4.5 Meter

- Hydraulic Press 400 MT

- Hydraulic Press 200 MT

Each component's bending profiles and contours are checked by Gauges.Few gauges are portable and a few are fixed type to ensure accuracy of bending. Records are maintained.

FABRICATION SHOP

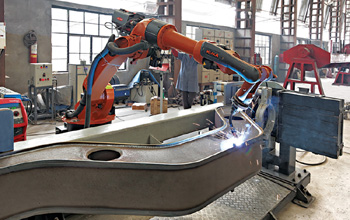

After fixing top plate External fillet/butt joints in welding manipulator of each sub-assy. Manual Mig/Robotic Mig with Argon-CO is employed.

Robotic Welding System

All Components after cutting, bending , pre machining and edge preparation are stocked in their respective sub-assy, tack welding stations and sequence of operations are as.

Fixture for Tack Welding for Side Frame of LHB Coach

Tack welding in fixture after clamping in X,Y,Z direction for each sub-assy.

Tack Welding Fixture for Side Frame of Loco Bogie

Welding of complete Bogie frame in special manipulator to enable downhand welding at all places.

- Jigs & Fixture designed by professional team of engineers.

- Periodic calibration and validation of jigs fixtures and gauges.

- Internal stage inspection records at each stage.

MACHINE SHOP

The Bogie Frame Assy is machined at all required location in single setting in horizontal/ vertical position in CNC Machining Centre with Auto heads having CNC Controlled 'A' and 'C' axis in Machining Centre with ATC.

- 3 Axis CNC Double column Machining centre with universal heads in A & C Axis having probing facilities. Size: 6200x3500x1000

- 5 Axis CNC Sliding Column Machining centre with Auto universal heads in A&C Axis having probing facilities. Size: 7000x4000x1500